Week 1!

Hey everyone,

Welcome back to the blog. This week we got the first of our parts and started figuring out how to work them.

Our list of parts for these week are:

- A pressure sensitive sheet that will be used for measuring the head pressure in our pillow.

- Solenoid valves that will be used for turning on and off the airflow into the pillow, in order to allow air to only come through when we want it.

- An air blower for actually inflating the pillow.

For this week, we spent a lot of our time just trying to figure out the pressure sheets. We first assumed that their pressure would be relatively small, so we put them in series with a 1000 ohm resistor, only to notice absolutely no change in voltage drop across the sheets whether we pushed on the pressure sheets or not. We finally decided to hook them up to the DMM and just measure resistance, which finally allowed us to realize that the resistance was in the 100k ohms range. The sheet itself and the resistance value when it was flat vs bent (effectively putting pressure on it) can be seen below.

Pressure sheet before pressure applied:

Resistance before pressure applied:

Pressure sheet after pressure applied:

Resistance after pressure applied:

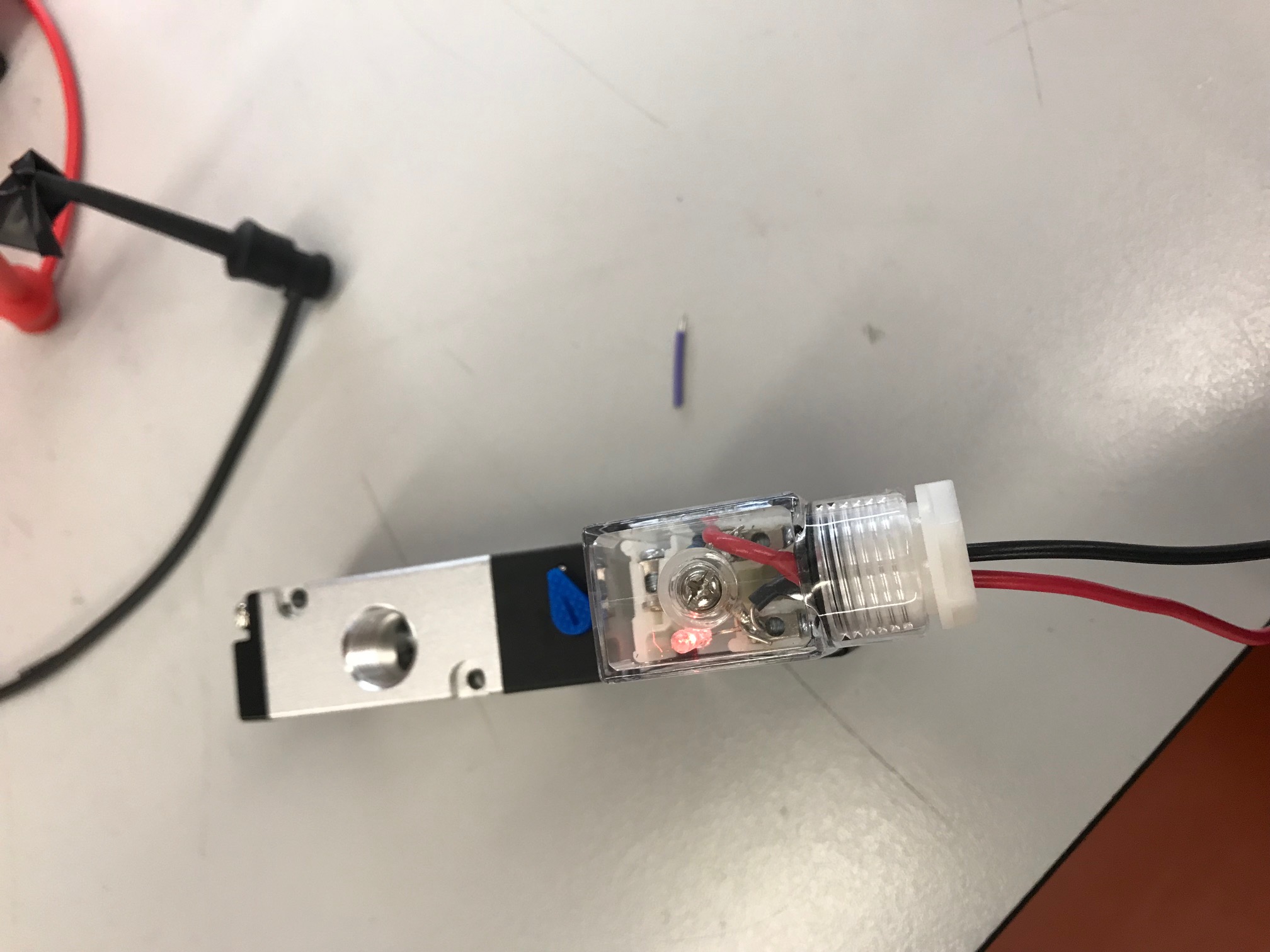

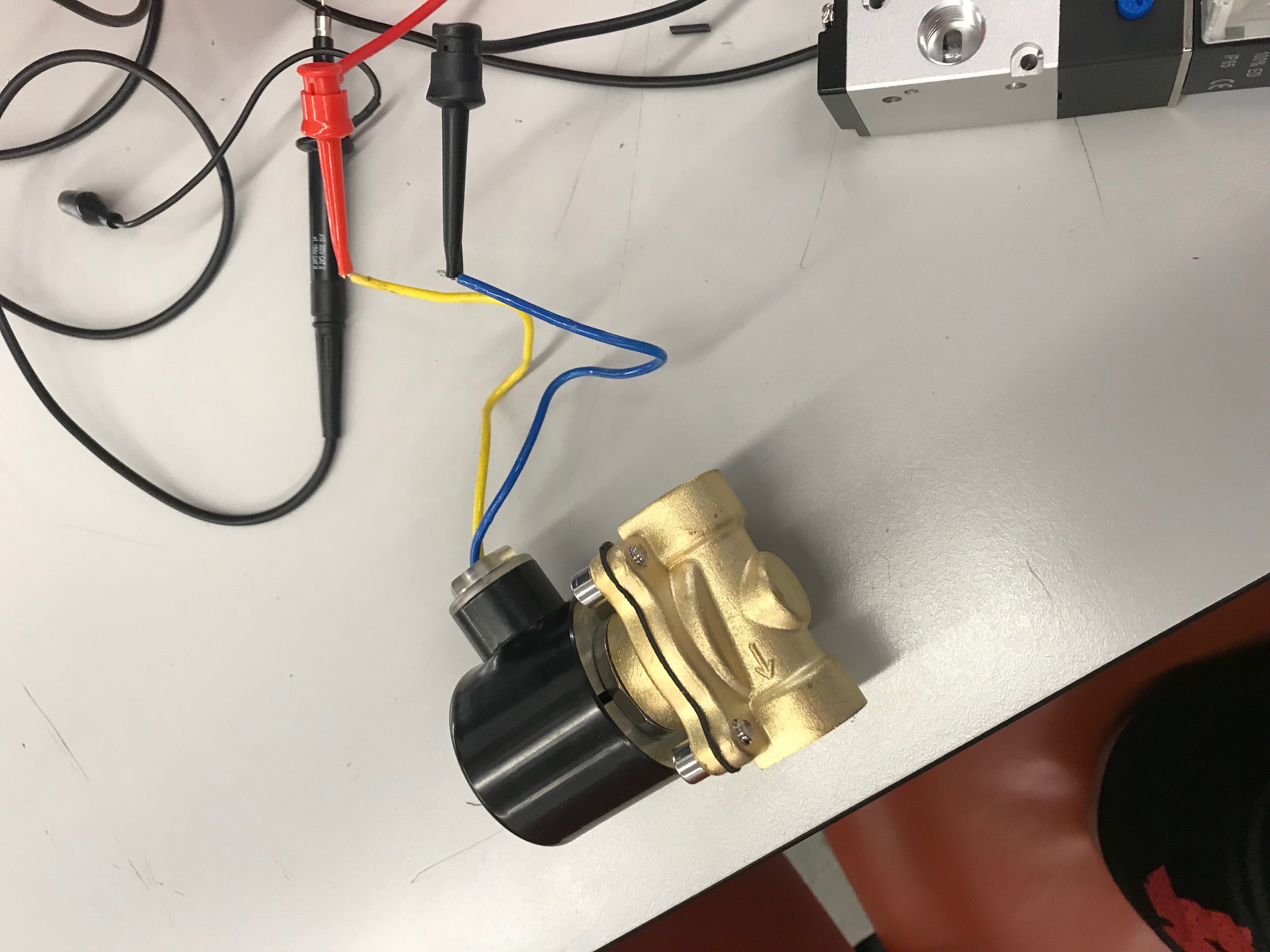

We then worked on soldering wires into our smaller solenoids and worked on getting them running and seeing if we could get them to switch from closed to open. While with our smaller solenoids we could get the light on (as seen below), a certain amount of pressure is needed to actually get it to switch from closed to open and we didn’t have the materials to do this yet. We had two different solenoids in order to make sure if one didn’t work we could still complete the project as well as the fact that the smaller ones are 3 way meaning we can use one solenoid for both exhaust and air supply.

Smaller solenoid:

Smaller solenoid hooked up:

Larger solenoid hooked up:

Finally, we wanted to make sure that, using the air blower, we could actually detect the difference in air going through the pipe when it was closed vs. open and we were able to do this by putting the air blower into the larger solenoid valve and cycling it from on to off (open to closed).

Air blower we decided to use plugged in: